What Tooling options are there?

Long gone are the days when the only tooling option was to use steel and these days, a wide variety of materials are used. Selecting the optimal tool material is dependent upon the quantities of parts required, the moulding material and any potential run-on requirements.

For really low numbers say up to 50, silicone is the obvious option, moulding parts in polyurethane. As quantities rise, one starts to look at hard tooling materials such as alumium and steel which allow the use of injection moulding and the full range of production materials.

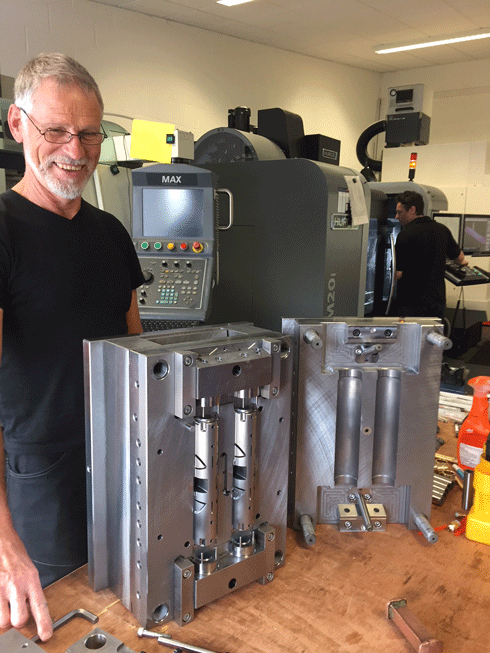

Aluminium Tooling (Bridge Tooling)

When aluminium is discussed in tooling applications it is important to differentiate between commercial grades and tooling grades as there is a world of difference.

Whilst aluminium is softer than steel, it can be machined faster, and generally worked more easily, offering the potential to reduce tooling costs and reduce leadtimes.

The term, Bridge Tooling is often used for a stage in development where there is a need for moulded parts in production intent materials, but production tooling is not yet available.

Often on new projects the quantities are far from certain, making justification of tooling spend difficult. Bridge tooling allows that toe in the water in order to 'bridge the gap' without the usual higher costs associated with steel tooling.

The result is a mould tool that costs less than a production tool, can be up and running in two to three weeks, and has the capability to produce from ten to a few thousand parts.

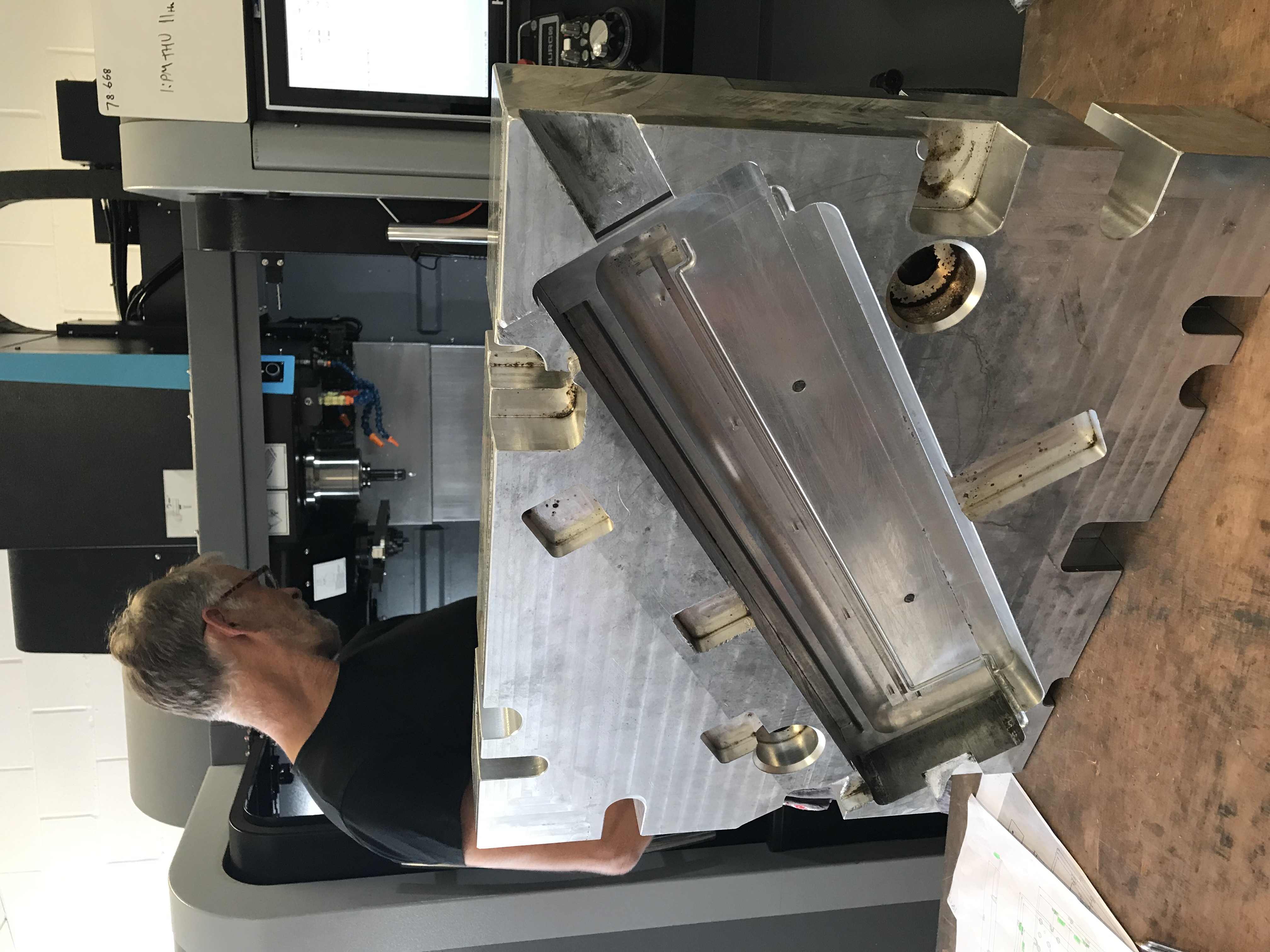

Steel (Hard Tooling)

Production tools are usually made of steel and intended for high volume production programs, or aggressive materials, and can be rated for millions of shots.

Sometimes the geometry or finish may demand the use of steel. This could be due to very thin wall sections or fine features where the materials inherent strength becomes a must have.

The lead-time to cut steel for a hard tool is longer, therefore the upfront cost is much more expensive. That said if the part quantities are really there, multi cavities, full lights out moulding and less maintenance all contribute to savings once production is underway.

How to decide which type of tooling you need?

* Geometry and complexity – Size drives cost, especially with hard tooling and the associated moulding presses become increasing costly. Complexity likewise can preclude other options.

* Time pressures – Remember a hard tool can take weeks to build, whereas soft tools can be produced in as little as a few days (depending on the complexity).

* Tool life and Quantities – Silicone tools are good for typically 25 shots of a part, aluminium tools can go from 10 to 100,000+, whereas steel tooling can take you into the millions.

* Required Finish – Most surface finishes can be recreated on an aluminium tool, however textured finishes will not last as long and its best to allow for an increased amount of draft to help with this.

* Materials – TPE,PP, ABS, PA, PC, PMMA for example all work well in aluminium, adding glass or ceramic fillers will question the use of steel tooling if the quantities are also there.

* Flexibility – Aluminium is frequently easier to modify, hence its use in bridge or development tooling when the design is less certain. Modifying production tooling should usually be avoided if possible.

Understanding what you need is important when considering what option to pursue. If you have a tight-tolerance part that is critical to the function of your system, cutting corners and cost in the development stage may not always save the money over the long term. Plunkett Associates have the knowledge and experience to advise and support with all your tooling requirements. We can sometimes offer some alternative solutions so please give us a call.