Custom enclosures - what can you offer?

It’s often a race against time to get enclosures for new products designed and manufactured. Waiting until electronics and internal workings are finalised can leave you very short on time, but the good news is, there are lots of options and Plunkett Associates is here to help.

What are the options?.jpg)

Some parameters such as strength, fire retardancy and ingress protection will be dictated by the product’s application. Others, such as cosmetics, design, and branding will depend on lead-time and budget.

Enclosure options range from standard off the shelf designs to using 3D Printing to create a highly customised case. Whilst each option has advantages and disadvantages, the perceived ideal is an injection moulded custom enclosure. Many people wouldn’t consider injection moulding for low volume, but we’re happy to dispel some of the myths, such as:

‘Injection moulding is too expensive’ – Actually moulding is likely to give the cheapest unit price per enclosure of all the options. It is the associated tooling that can seem expensive, but there are ways to address this. For example, using a standardised mould frame negates the need for a bolster. Alternatively using loose inserts within the tool can save on automating the release of undercuts or threads.

‘My quantities are too low’ – Plunkett Associates has moulded batch sizes down as low as 50.

‘I do not have time’ – If the design is in place, tooling can be completed in two weeks.

‘I do not have a designer’ – Plunkett Associates can offer support on Solidworks to generate a design from your concept or interface requirements.

There are many advantages to a custom moulded enclosure, including the fact that there are a wide range of materials and finishes available, which can be complemented with screen printing or labels. The quality/finish is similar to mainstream high volume products and the geometry can be tailored to suit the particular electronics, connectors, and displays. Sealing (Ingress Protection) can also be addressed if required.

There are many advantages to a custom moulded enclosure, including the fact that there are a wide range of materials and finishes available, which can be complemented with screen printing or labels. The quality/finish is similar to mainstream high volume products and the geometry can be tailored to suit the particular electronics, connectors, and displays. Sealing (Ingress Protection) can also be addressed if required.

The Key to Success

The key to success is in the design and ensuring that this is optimised for the process. Thus whether working from concept sketches or a detailed design (destined of CNC machining or 3D Printing) the manufacturing process has a very significant bearing. Ensuring that the interfaces are defined, i.e. size of pcb, fixing points, screen location, switch/button size and operation, will also help.

If the design already exists, but is based on a different process, then we will need to review it to see whether injection moulding is feasible. The process is usually relatively quick and prevents expensive issues being rectified at a later date.

We’ll check whether the part contains undercuts that can be re-engineered, wall sections that will give rise to sinkage, negligible draft and/or be devoid of fillet radii. We may discover that the part is mouldable, but the resultant tooling will have very thin walls, or vulnerable features – although these can be rectified if identified early enough. Parting lines will be a consequence of draft and geometry, but also need to be checked against the parts cosmetic requirements.

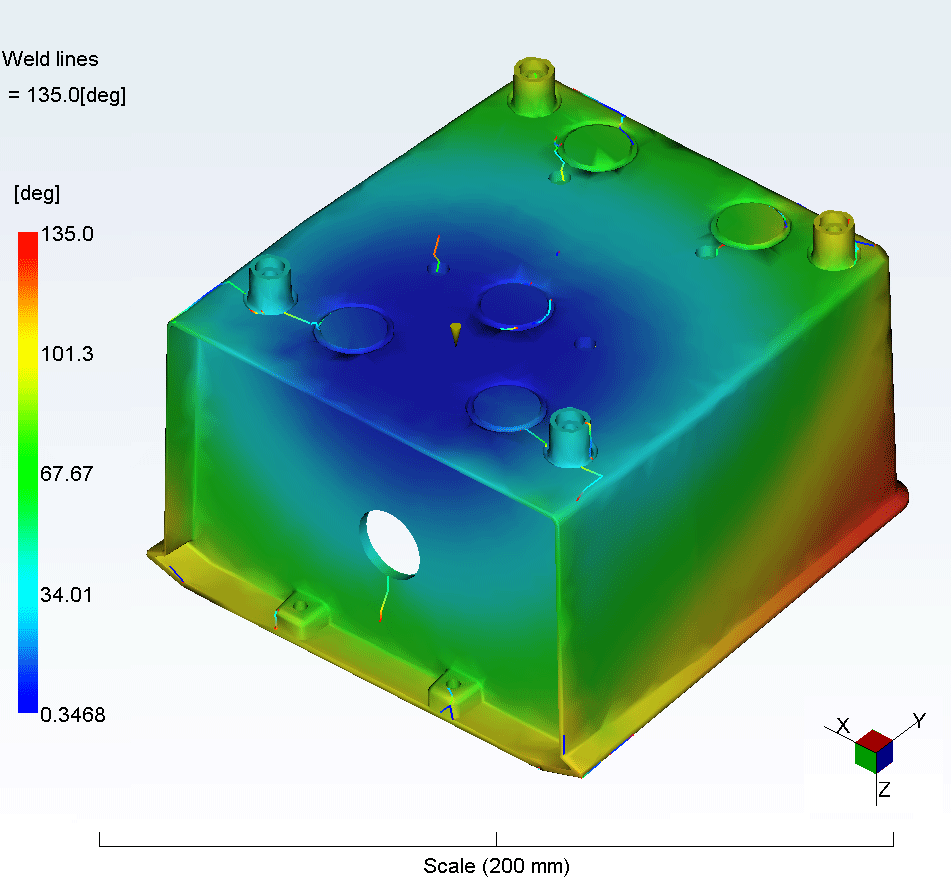

Should the geometry warrant it, Plunkett Associates can then run the part through Moldflow to look at how the part will fill. This not only provides a ‘confidence of fill‘, but illustrates where potential weld lines will occur, ramifications of selecting certain gate locations, injection pressure, time of fill and gives an overall quality prediction.

What happens next?

Given a mouldable part, the next step is to decide how and where to undertake the tooling and moulding. Options include UK or the Far East, aluminium or steel, and manual or fully automatic. Factors such as quantity required, future call off, material availability, post moulding operations (screen printing, inserts etc), size and customer preference all influence the decision.

Plunkett Associates will supply quotations that include initial samples and importation costs if appropriate. We will also manage the entire process from initial order to final delivery.

How much and how long?

Cost and leadtime are very specific to each project. However, if we were to take a simple two piece enclosure comprising a back box and bezel, that was subject to no special sealing requirements, then design, tooling and first off parts can be achievable in 3 – 5 weeks and at a cost of between £4,000 and £6,000.

The danger of suggesting costs is that everyone translates it against their particular components, so please get in touch if you have a specific project in mind. Yes, we can go faster and yes, some tools will cost a lot less. However, it is also true to say others will take longer and cost substantially more!

The more information you can supply, the quicker we can get it made. Low volume does not mean you cannot have a unique, injection moulded enclosure, to brand and promote your product.